Business Case Studies

- Gas for Business >

- Business Case Studies

Natural Gas Helps Fuel Lion Brewery’s Growth

A Pennsylvania brewery with a long history of making beer is now pumping out beverages of a different kind: carbonated drinks by the case. Fueling this 24/7 drink production is natural gas. A new larger natural gas line, installed by UGI, running into a recently opened canning line facility provides the energy needed to produce steam. Lion Brewery uses steam across its production, from pasteurization to dissolving sugar. Read more about how Lion Brewery is benefitting from natural gas.

Combined Heat and Power for Higher Education: Bucknell University

In the late 1990s, Bucknell replaced its aging coal-fired campus power plant with a $12 million natural-gas fired Combined Heat and Power (CHP) plant, achieving a 97% reduction in plant emissions and annual savings of $1 million in electricity costs. The University was one of the first in the region to adopt this technology, which included a combustion turbine to supply a heat recovery steam generator, a steam turbine generator, two supplementary boilers, and a sophisticated control system. Read more about Bucknell's CHP system.

Natural Gas Vehicles for Public Transit Agencies

Every year, millions of rides are provided to Pennsylvania residents who rely on public bus service to transport them where they need to go. Behind that service are hundreds of millions of dollars in annual operating costs, including tens of millions in fuel costs. In recent years, rising prices and high volatility of gasoline and diesel prompted the Pennsylvania Department of Transportation (PennDOT), which funds PA’s transit agencies, to investigate alternative fuels. Considering PA’s easy access to low-cost and abundant natural gas supply, the solution was clear. Read more about PennDOT's investment in natural gas vehicles.

CNG Vehicles: Waste Management

In 2007, Waste Management unveiled a progressive set of sustainability goals, including the commitment to lower the fleet emissions by 15% by 2020, translating to a reduction of 3.5 million metric tons of CO2 emissions, $1 billion in operational costs and 350 million gallons of diesel fuel. Just four years later, the initial goal was surpassed, nine years early, facilitated by the transition of their fleet vehicles to natural gas. Read more about Waste Management's transition to CNG vehicles.

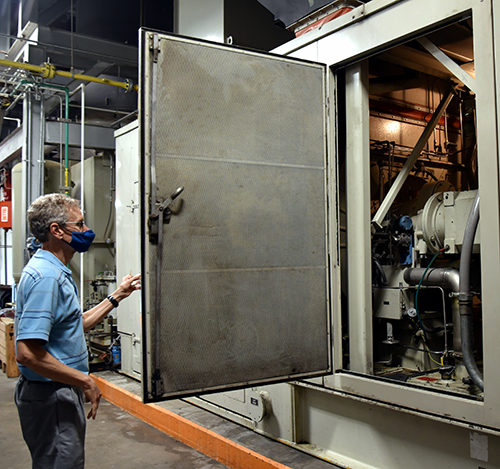

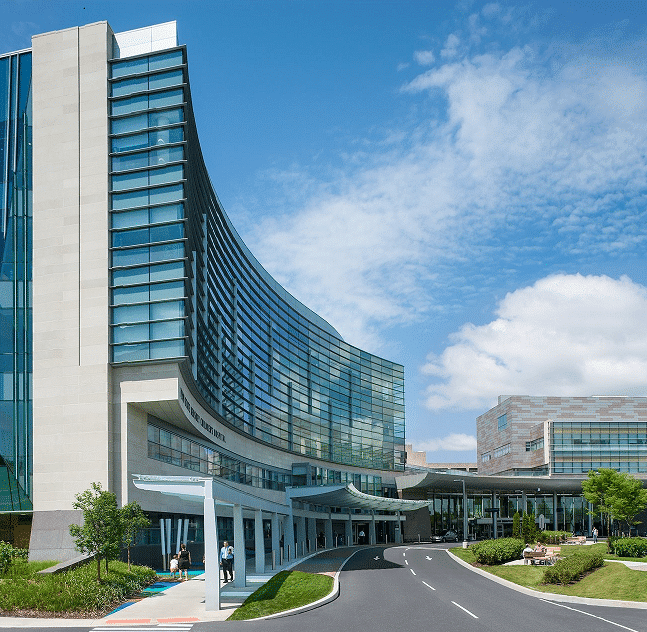

Combined Heat and Power for Medical Facilities: Hershey Medical Center

Known as the premier provider of medical care in the central Pennsylvania area - recognized as the number four hospital in the state and home to PA’s only medical facility accredited as both an adult and pediatric Level 1 Trauma Center – Penn State Hershey Medical Center is also focused on caring for the environment. Demonstrating their commitment to both top notch patient care and sustainability, the medical center invested in a cogeneration facility to minimize their energy footprint. Read more about Hershey Medical Center's CHP system.

KRE Madison Farms: Multi-Family Construction

A forward-thinking developer of luxury properties, the KRE Group began their endeavor to incorporate natural gas appliances as a best practice in their multi-family properties with Madison Farms, a high-end community in the Lehigh Valley. Ingenuity, planning and rebates offered by UGI Utilities resulted in a successful pursuit and an adoption of new best practices. Read more about the benefits natural gas provided to the KRE Group.

Gatorade Plant to Reduce Emissions by 20%

The Gatorade Company, Inc., a division of PepsiCo, completed construction of combined heat and power (CHP) system at its processing plant in Mountain Top, PA in November 2016. The objective of this project was to reduce cost and to help achieve their goal to reduce greenhouse gas emissions 20% by the year 2030. Read more about PepsiCo's CHP system.